As I finished pouring the soap batter into the soap mold, I realized that I just completed a creative process. And it would be within 24 to 36 hours that I will see the result of that process.

That creative process is the background of what you don’t see in the finished product. So, as I continue my journey as a diy soapmaker, I want to talk about my process and some of what goes on behind the scenes.

Formulation: When I formulate a soap recipe, I have three basic requirements that must be met to get those qualities that I want in the soap. My bars need to be hard, lathering, and moisturizing. So, I use soapcalc.net to help me achieve those requirements.

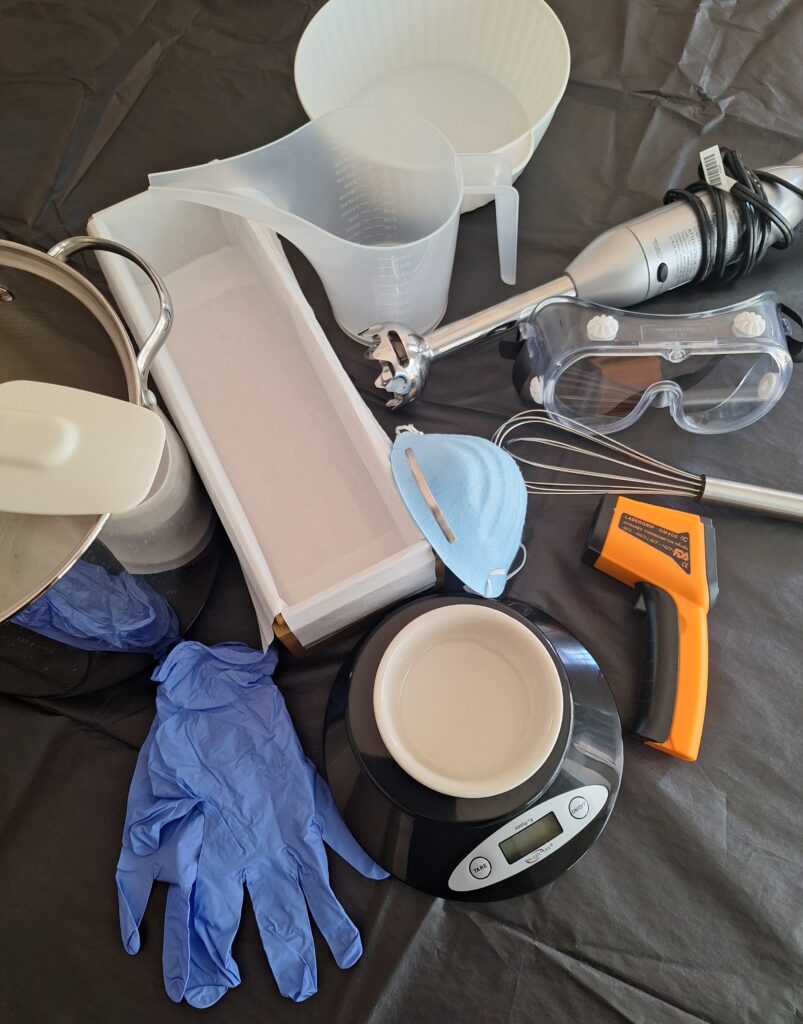

Equipment: Preparing the equipment needed to make soap. Stick blender to blend the ingredients, and a mask to protect from inhaling the fumes from the lye. Goggles to protect from anything splashing in my eyes, gloves, bowls, scale, soap mold, spatula, and a thermometer, to name a few.

Ingredients, & Lye: Precisely weighing the fats, oils, fragrance, distilled water, lye, botanicals, exfoliants, colorants, etc. Melting the oils and fats; and pouring the lye into the distilled water. Of all the ingredients used in soapmaking, you must be very careful with handling lye.

Cleanup: This is not my favorite part. I scrape off any soap batter that is left on the equipment. Then the equipment is washed with a liquid detergent to remove the grease.

This is what goes on each time that I make soap. And it is with great anticipation that I wait for the unmolding of the soap.

Leave a Reply